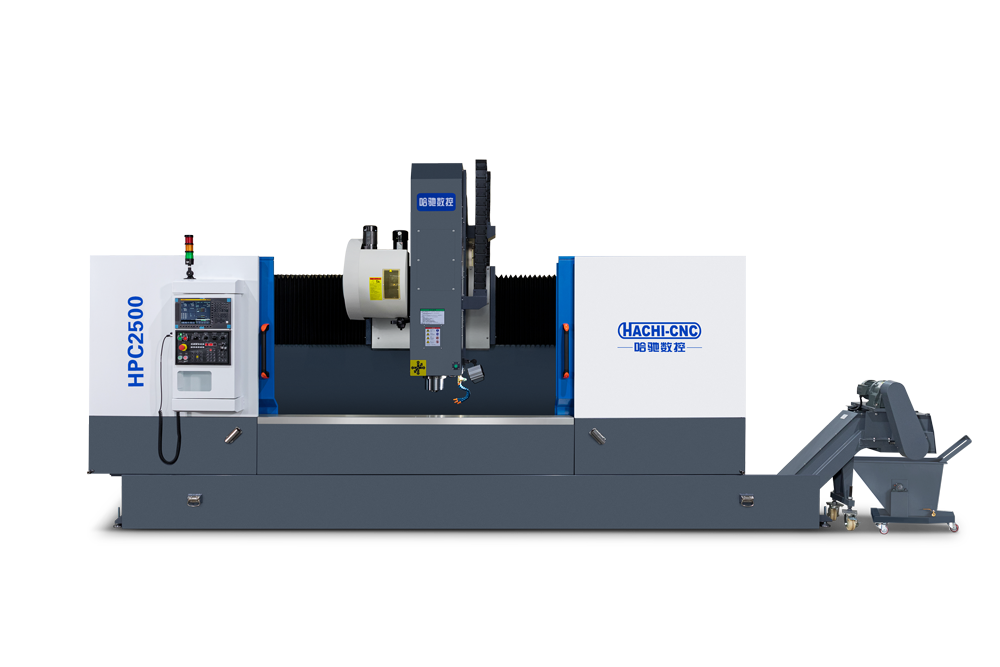

| Project | Unit | Parameter |

| Itinerary | X-axis (spindle moves left and right) | Mm | 2500 |

| Y-axis (the spindle moves back and forth) | Mm | 600 |

| Z-axis (spindle moves up and down) | Mm | 700 |

| The closest distance from the nose end of the spindle to the end of the workbench | Mm | 150 |

| T-slot | T-slot width | Mm | 18mm |

| T-type slot number/center spacing | Mm | 2/320mm |

| Inward | Three axes |

| Unknown | Y | Z |

| Fast movement speed | M/min | 36 | 28 | 28 |

| Maximum feed speed | M/min | 36 | 28 | 28 |

| Cutting feed | Mm/min | 1~15000 | 1~15000 | 1~15000 |

| Positioning accuracy (the whole process) | Mm | 0.02 | 0.01 | 0.01 |

| Repeated positioning accuracy | Mm | 0.02 | 0.02 | 0.02 |

| Three-axis drive | Three-axis servo motor | Rated power | Kilowatt | 3 | 3 | 3 |

| Maximum torque | N.m | 68 | 45 | 45 |

| Maximum output speed | Rpm | 3000 | 3000 | 3000 |

| Spindle servo motor | Spindle power | Kilowatt | 11/18.5 |

| Rated torque | N.m | 52.5 |

| Maximum torque | N.m | 118 |

| Maximum output speed | Rpm | 12000 |

| Main axis | Maximum rotational speed | Rpm | 12000 |

| Spindle diameter | Mm | 150 |

| Transmission mode |

| Direct form |

| The method of drawing a knife |

| BT40 four-valve claw |

| Spindle hole |

| Taper 7/24 taper NO.40 |

| Spindle balance level |

| G1 (ISO1940) |

| Installation method |

| Vertical |

| Knife library | Knife warehouse form |

| Disc type |

| Knife handle specifications |

| BT40 |

| Number of knives | Hold | 24 |

| Maximum tool diameter (full knife)/length/weight | Mm, kg | Φ80mm/300mm/8kg |

| Diameter of adjacent empty knife | Mm | Φ125 |

| Knife change time (knife to knife) | Sec | 1.8 |

| Reduction ratio of knife changer reducer |

| 1:08 |

| Cooling and lubrication power | Electric power | KVA | 30 (380V, 50Hz) KVA |

| Gas source | Master of Public Administration | 0.6Mpa-0.9Mpa |

| Screw lubrication |

| Automatic rail oil lubrication device |

| Guide rail lubrication |

| Automatic rail oil lubrication device |

| Cooling motor power | Kilowatt | 0.75 |

| Cutting and cooling |

| Water-spray cutting cooling system |

| Machine tool size | Machine tool height (Z-axis positive limit) | Mm | About 3700 |

| Machine tool width (Y-axis negative limit) | Mm | About 3400 |

| Length of the whole machine + chip removal machine | Mm | About 6100 |

| Weight of the whole machine | Kilogram | About 10,000 |

| Machine tool operating environment requirements | Power supply requirements |

| 3Φ380V 50HZ |

| Operating ambient temperature (average temperature not higher than 35℃ within 24 hours) | ℃ | 5~40 |

| Relative humidity of operating environment | % | 30—75 |

| * Vibration intensity |

| Less than 0.5G |

| Stay away from dusty, corrosive/organic gas environments |

| Grounding resistance | Less than 10 ohms (need to be grounded separately, not grounded in series) |